获得高性能而采用伺服阀并联方式的可行性及可能的问题

笔者在项目实践中进行过六个伺服阀并联控制振动缸,可以达到70Hz。这种并联控制方式是没有问题的。

不过在细节上需要对阀的接线方式,阻抗,控制器的接线方式和输出阻抗进行匹配设计(具体参见楼上PEN的说明。并对阀的性能和控制器的性能都要有足够深度的了解。如果您有这方面的具体项目需求,可以联系我们提供具体的计算和建议。

- 本文出自爱液压论坛,原文地址:http://www.iyeya.cn/thread-43787-1-1.html

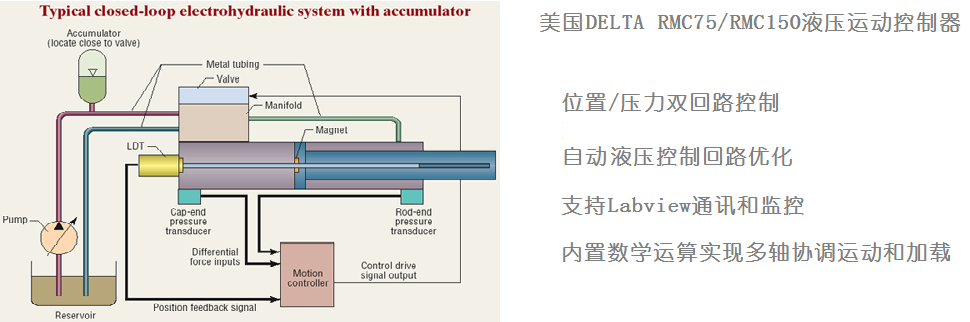

下面的文章转自美国DELTA的Peter总裁在《爱液压》论坛上发表的对并联伺服阀控制的建议

Using two servo valves in parallel is a good idea.

if

1. You cannot find a bigger valve.

2. The two smaller valves are faster or more linear than the bigger

valve.

3. The null of the two valves can be adjusted to be the same.

Any two servo valves can be used in parallel but it is best if they

are the same type.

The hydraulic servo controller will not have any problems with

control. It will treat the two or more valves in parallel as one

big valve.

The problem is the control signal to the valves. Current and

voltage limits cannot be exceeded. Servo valves with voltage inputs

usually have high impedence so a +/- 10 volt signal can go to two

valves wired in parallel. When the two valves use current it is

best to wire the two valves in series so the same current goes to

each valve. However, there are two coils inside the servo valve.

These may need to be wired in parallel because four coils in series

would exceed the voltage capabilities of the controller

output.

In one case the customer wanted to wire the two servo valves in

parallel so if the wiring in one valve failed the other valve would

still work. I didn't think this was a good idea but this is what

the customer wanted. In this case the coils in the servo valve

should be wired in series otherwise the current requirements may

exceed the capability of the controller current output.

a = F/m

a = (Pa*Aa-Pb*Ab)/m

----------------------------------------------------------------------------------------------------------------

北京市思路盛自动化系统集成有限公司